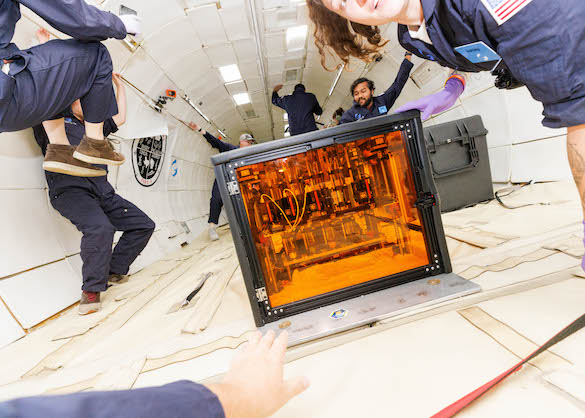

Evaluation of Computed Axial Lithography for rapid, volumetric additive manufacturing under low-gravity conditions

PI: Hayden Taylor, Taylor Waddell (Co-I), University of California - Berkeley

PI: Hayden Taylor, Taylor Waddell (Co-I), University of California - Berkeley

- NA

Additive manufacturing in space allows astronauts to efficiently build or repair needed items during a mission without having had to bring those items with them from Earth. Some additive manufacturing techniques can even be used to fabricate parts of human organs, which could be critical for a crew member with organ damage on a long-duration mission.This technology could improve current space-based bioprinting techniques, which have the potential to alter cell growth or are not readily adaptable with a wide variety of materials.

Parabolic flight tests willexplore the effects of reduced gravity on the technology’s sedimentation,resin flows, print fidelity,and degree of conversion, with a particular focus on low-viscosity resins that are more challenging to print under normal gravity conditions.Overall, testing in microgravity aims to mature CAL to TRL 6. Doing so will advance its scalability,modularity, and versatility in printing both biomaterial and engineering components in the same machine.

Producing flexible components like gaskets and seals

Tissue modeling research

Bioprinting human organs

Printing dental components

Technology Details

-

Selection DateTechFlights20 (Sep 2020)

-

Program StatusActive

- 3 Parabolic

Development Team

-

PIHayden Taylor

-

PI Organization

-

Co-ITaylor Waddell

-

Co-I Organization

-

SponsorNASA

-

More Information