Advanced Two-Phase Heat Exchangers Design Tools

PI: Jungho Kim, University of Maryland - College Park

PI: Jungho Kim, University of Maryland - College Park

- TA11 Modeling, Simulation, Information Technology and Processing

- TA14 Thermal Management Systems

The primary objective of the experiment is to understand the major mechanisms of heat transfer during flow boiling in a reduced gravity environment. Better understanding of how the heat transfer mechanisms change between earth normal gravity, hypergravity, and low-gravity environments and the quantification of parametric effects such as heat flux, inlet subcooling, inlet mass flux, will enable the design of two-phase heat exchangers to proceed with much more confidence.

The experiment would be in preparation for the design and flight of an ISS based experiment (TRL 5). The data provided by the experiment would help identify the actual issues that require further attention before the flight experiment is designed and built.

Results of the work can serve as benchmarks to validate analytical and/or numerical codes, and will impact the ability to reliably engineer the energy rich systems for future space missions.

Unlike previous work where only time- or space-averaged heat transfer data were measured, we will obtain local measurements of the wall heat transfer coefficient with high temporal and spatial resolution. Visualization of the flow will allow the heat transfer to be correlated with the flow regime. An IR camera will be used to visualize fluid flow within a silicon tube and obtain temperature distributions along the inside and outside walls of the tube so local heat transfer coefficients can be determined.

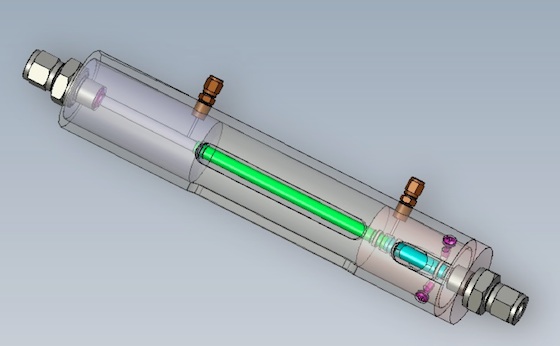

The silicon tubes used to heat the fluid as well as visualize the flow are made of approximately 5 ohm-cm bulk silicon. The tubes are 6 mm ID with 1.0 mm thick walls. A test section that holds the silicon tube and allows IR measurements is shown schematically below. The green tube represents the silicon tube, and the blue tube is a quartz tube used for film thickness measurement.

Technology Details

-

Selection DateAFO1 (May 2011)

-

Program StatusCompleted

- 2 Parabolic

Development Team

-

PIJungho Kim

-

Organization

-

SponsorNASA