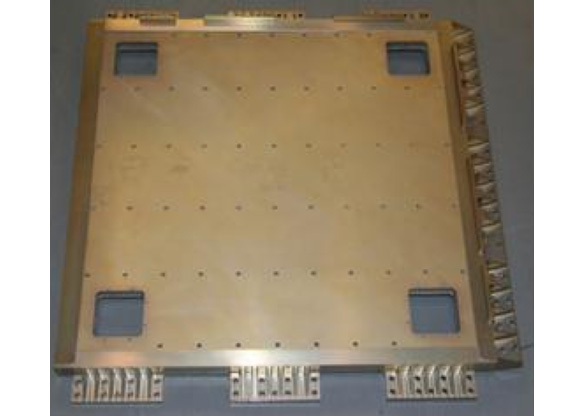

Resilient Thermal Panel: Microgravity Effects on Isothermality of Structurally Embedded Two Dimensional Heat Pipes

PI: Andrew Williams, Air Force Research Laboratory - Kirtland

PI: Andrew Williams, Air Force Research Laboratory - Kirtland

- TA14 Thermal Management Systems

By reducing thermal gradients, an isothermal bus can increase the life of components and lead to more efficient operations. To achieve these benefits, flat heat pipes have been embedded in a composite structure which increases the effective conductivity of the material without adding parasitic mass. A grid pattern on the exterior of the panel allows for attaching electronic components as needed. It is well known that the behavior of two-phase flows is quite different in microgravity, and this could affect the performance of the embedded two dimensional heat pipe. Because gravity effects influence the distribution and the behavior of the fluid and vapor in the Resilient Thermal Panel channels, ground testing skews test results by 15% or more compared to thermal/ fluid model predictions because of pooling, thermosiphon, and other gravity effects.

The anticipated outcome of the proposed experiment is a better understanding of how microgravity will affect the performance of a two phase flow in microgravity and specifically wicked two dimensional heat pipes. Of particular interest is a better understanding of the physics of the two dimensional heat pipes and determining if any of the thermal performance is due to convection as observed in thermosiphons.

Resilient Thermal Panel is an adaptable, cross-cutting technology that can be applied to all high-power spacecraft, cutting weight and increasing power capabilities for nearly all future missions.

Technology Details

-

Selection DateAFO6 (Jun 2013)

-

Program StatusCompleted

- 1 Parabolic

Development Team

-

PIAndrew Williams

-

Organization

-

SponsorAir Force Research Lab / Space Vehicles